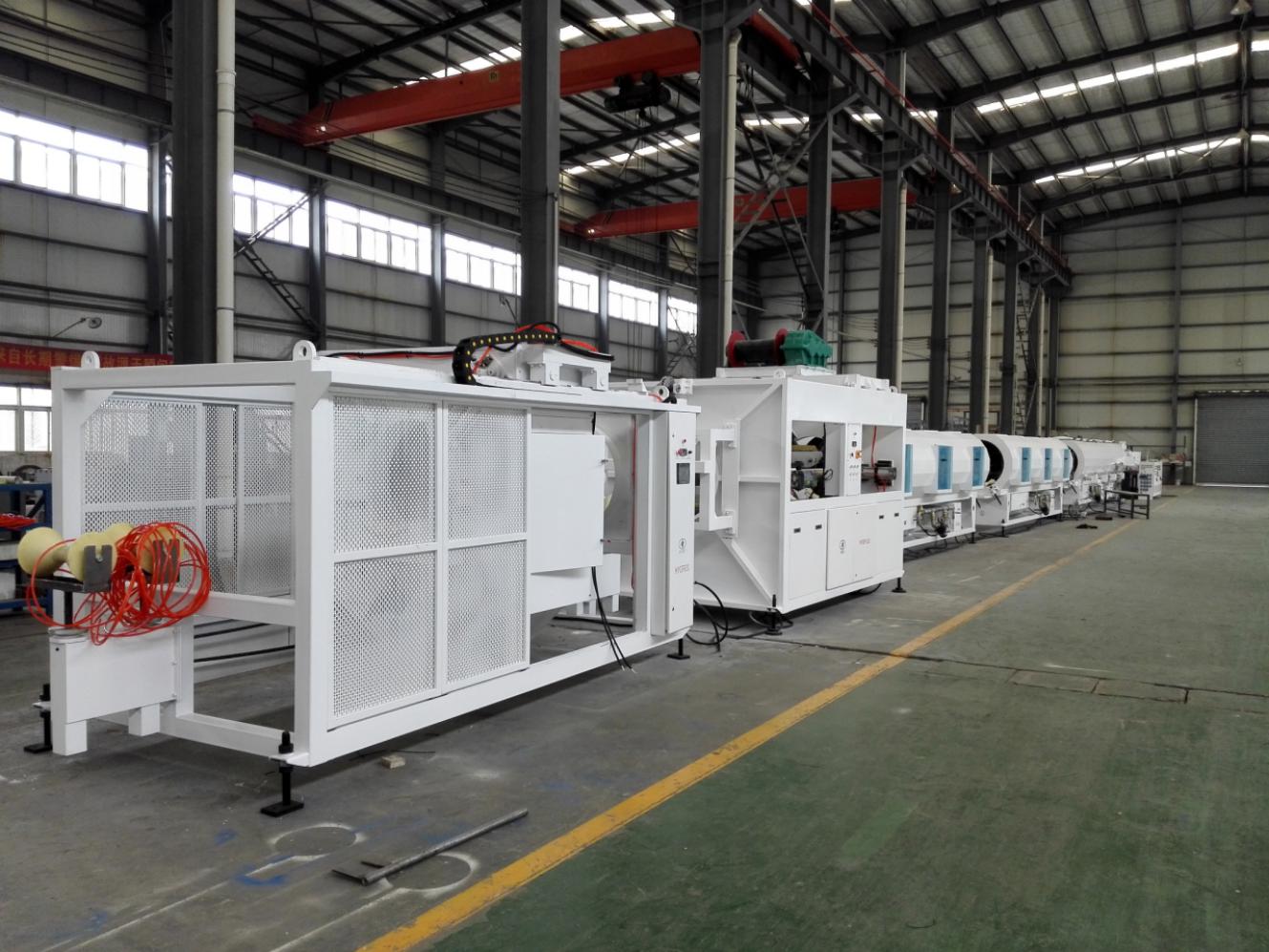

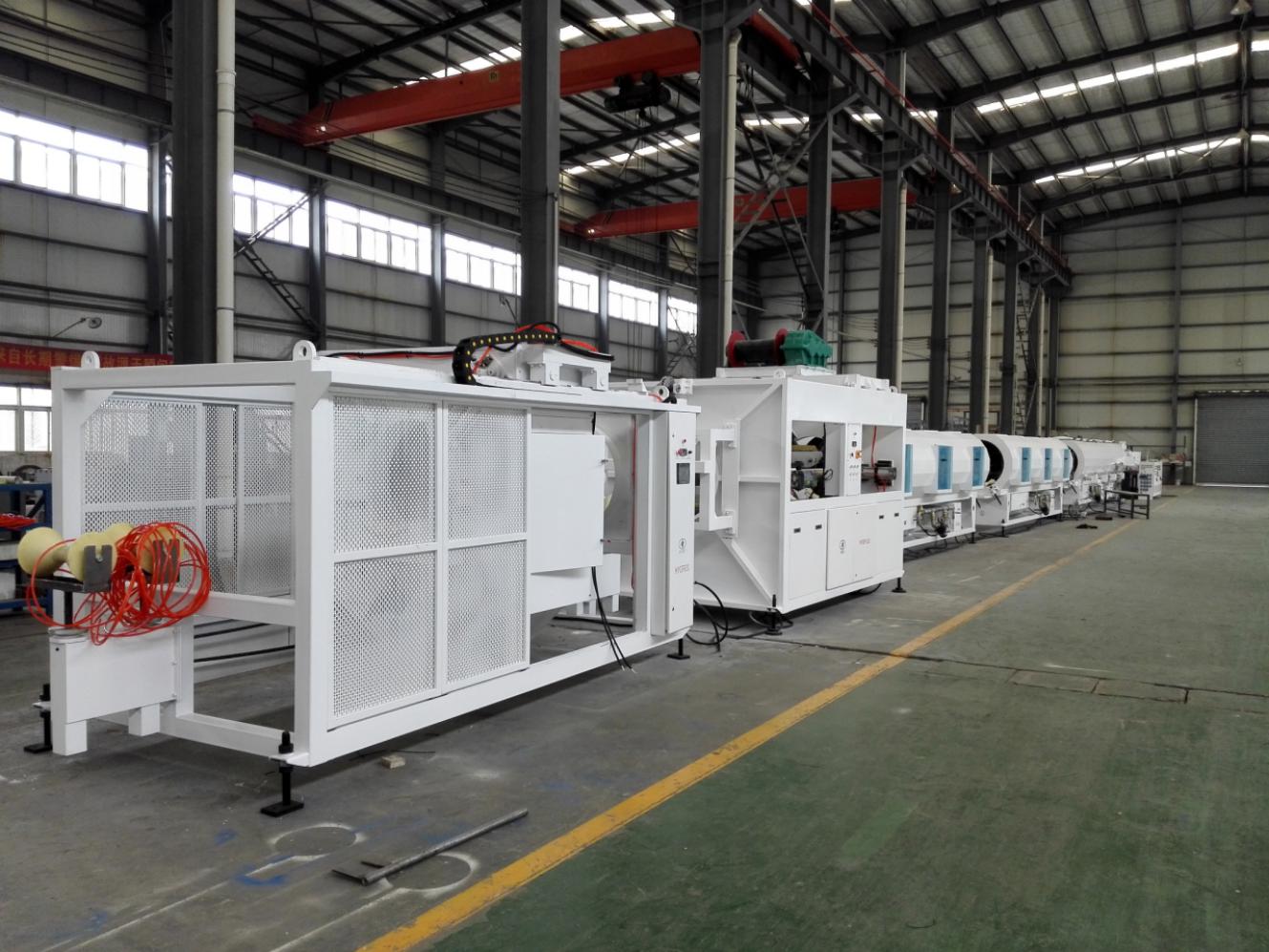

HYSJ90/38 Single screw extruder with Three layers ABC type 315-630mm HDPE PE gas pipe water supply

pipe production line:

| SN | Main Items | Qty |

| 1 | Single screw extruder HYSJ 90 / 38, 250kW motor power | 1 set |

| 2 | Gravimetric Dosing unit in Chinese made | 3 sets |

| 3 | Single screw extruder HYSJ 60 / 37, 45kW motor power | 1 set |

| 4 | Single screw extruder HYSJ 45 / 33, 30kW motor power | 1 set |

| 5 | Single screw extruder HYSJ 30 / 25, for color strip | 1 set |

| 6 | Automatic Feeder and Drier for big machine | 1 set |

| 7 | Automatic Feeder and Drier for smaller machine 100-200L | 2 sets |

| 8 | Extruder Die: G630, in 3 pressure grade | 1 set |

| 9 | Vacuum tank 12 m | 1 sets |

| 10 | Spray cooling tank in 6,000 mm | 3 sets |

| 11 | Haul off unit, 6 claw type in servo control system | 1 set |

| 12 | Planetary dustless cutter | 1 set |

| 13 | Stacker | 1 set |

Remarks:

1. Condition of the price and destination Ex-works Wuhan China

2. Payment method: 30% of the total will be paid by T/T as deposit,

the balance will be paid after testing and before shipping by T/T

or by irrevocable L/C on time .

3. Delivery period: 70 days after received the deposit.

4. Validity period: 30 days after ensured

5. Warranty: one year for normal, barrel and screw and gear box is

for 1.5 years

6. Training: both in china and in the customer shop are available.

7. If necessary, The supply can send the engineers to the buyer for

commission under the condition.

Technical specification:

1.HYSJ-90/38 single screw extruder:

| SN | Parts name | Image | Specification | Description |

| 1 | Extruder | | Extruder model | HYSJ-90/38 single screw |

| Output Max | 970 kg/h |

| Center height | 1,100mm |

| Weight | 4,300kg |

| 2 | Screw | | Diameter | Ø90 mm |

| Screw ID ratio | 38:1 |

| Material | 38CrMoAlA + special alloy |

| Finish | Nitrogen-filled (0.50~0.70mm depth) and polish |

| Max rotate speed | 125 r/min |

| Core of the screw | Auto control for temperature |

| Features | 1. German technology design, to ensure the highest output and good

good plasticizing at the same power. 2. 38CrMoAlA nitriding HV900, depth 0.4-0.6mm surface sprayed

alloy; |

| 3 | Barrel |

| Material | Bimetal barrel inside in two layers |

| Inside finish | Nitrogen-filled (0.50~0.70mm depth) |

| Heating control area | 9 areas |

| Heating way | Copper cooling fins with ceramic heater |

| Heating power | 40 kW |

| Cooling system | Low-noisy barrel cooling fan |

| Cooling power | 0.55kW x 9 sets |

| Features | 1. Inner casting alloy bimetal barrel can ensure 24 months; 2. With HYPET special feeding device, with large feeding quantity,

good cooling, easy replacement, low maintenance costs. 3. Adopt cast aluminum heaters, high cost but fast heating, high

temperature can be controlled. |

4

| Gear box

| | Housing material | Ductile iron QT-500 |

| Gear material | 20CrMnTi |

| Gear surface | Hardened and ground in high precision |

| Axis material | 40Cr |

| Cooling power | 0.55kW x 9 sets |

| |

| 5 | Driving motor | | AC motor power | 250 kW |

| AC inverter controller | Siemens brand |

HYSJ60/37 single screw extruder:

| SN | Parts name | Image | Specification | Description |

| 1 | Extruder | | Extruder model | HYSJ-60/37 single screw |

| Output | 180 kg/h |

| Center height | 1,150mm |

| Weight | 2,300kg |

| 2 | Electrical Control system |      | Detachable control panel | Digital display, adjusting knobs |

| Components brand | Siemens, RKC, ABB, etc. |

| Note: PLC computer control system can be optional. |

| Features | 1. Cabinet is detachable, easy to install, maintain and transport; 2. With air conditioner; 3. Adopt the world famous brand electrical components, such as

Siemens, ABB, RKC Schneider, and so on. |

| 3 | Screw | | Diameter | Ø60 mm |

| Screw ID ratio | 37:1 |

| Material | 38CrMoAlA + special alloy |

| Finish | Nitrogen-filled (0.50~0.70mm depth) and polish |

| Max rotate speed | 108 r/min |

| Core of the screw | Auto control for temperature |

| Features | 1. German technology design, to ensure the highest output and good

good plasticizing at the same power. 2. 38CrMoAlA nitriding HV900, depth 0.4-0.6mm surface sprayed

alloy; |

| 4 | Barrel | | Material | Bimetal barrel inside in two layers |

| Inside finish | Nitrogen-filled (0.50~0.70mm depth) |

| Heating control area | 6 areas |

| Heating way | Copper cooling fins with ceramic heater |

| Heating power | 15 kW |

| Cooling system | Low-noisy barrel cooling fan |

| Cooling power | 0.25kW x 6 sets |

| 5 | Gear box | | Housing material | Ductile iron QT-500 |

| Gear material | 20CrMnTi |

| Gear surface | Hardened and ground in high precision |

| Axis material | 40Cr |

| 6 | Driving motor | | AC motor power | 45 kW |

| AC inverter controller | Siemens brand |

HYSJ45/33 single screw extruder:

| SN | Parts name | Specification | Description |

| 1 | Extruder | Extruder model | HYSJ-45/33 single screw |

| Output | 100 kg/h |

| Center height | 1,150mm |

| Weight | 1,800kg |

| 2 | Electrical Control system | Detachable control panel | Digital display, adjusting knobs |

| Components brand | Siemens, RKC, ABB, etc. |

| Note: PLC computer control system can be optional. |

| 3 | Screw | Diameter | Ø45 mm |

| Screw ID ratio | 33:1 |

| Material | 38CrMoAlA + special alloy |

| Finish | Nitrogen-filled (0.50~0.70mm depth) |

| Max rotate speed | 98 r/min |

| 4 | Barrel | Material | Bimetal barrel inside in two layers |

| Inside finish | Nitrogen-filled (0.50~0.70mm depth) |

| Heating control area | 5 areas |

| Heating way | Copper cooling fins with ceramic heater |

| Heating power | 12 kW |

| Cooling system | Low-noisy barrel cooling fan |

| Cooling power | 0.25kW x 5 sets |

| 5 | Gear box | Housing material | Ductile iron QT-500 |

| Gear material | 20CrMnTi |

| Gear surface | Hardened and ground in high precision |

| Axis material | 40Cr |

| 6 | Driving motor | AC motor power | 30 kW |

| AC inverter controller | Siemens brand |

2.HY30/25 single screw extruder:

| Specification | Description |

| Barrel | 38CrMoAIA,nitrification |

| Screw | 38CrMoAIA,nitrification |

| Dia. of screw | Ø30mm |

| Screw L/D | 25:1 |

| The drive power | 2.2 kW |

| The motor control | AC inverter, ABB |

3.Vacuum auto loader :

| Specification | Description |

| Model | AL1000 |

| Working form | Inductive type |

| Power | 2.2kw, 3P |

| Capacity | 1200kg |

| volume | 5L |

| Feeding hose diameter | Ф38mm |

4.Vertical Hot dryer:

| Specification | Description |

| Model number | HY-HD2000 |

| Capacity | 2000 kg |

| Heating | 50kW |

| Blower | 3W |

| Power | 380V 3P 50HZ |

5.Die head: G250 high speed in 2 pressure grade:

| Specification | Description |

| Pipe type | 3 layers in A+B+C |

| Sizes for pipe | Ø250-630mm |

| Calibrator each for the sizes | Ø315 Ø355 Ø400 Ø450 Ø500 Ø560 Ø630 |

| Sleeve , each for the sizes | Ø250-315,Ø355-450,Ø500-630 |

| Mandrel each for the sizes | Ø250,Ø280,Ø315,Ø355 Ø400 Ø450 Ø500 Ø560 Ø630 |

| Material of die head | 40Cr with special alloy |

| Heating power | 120 kw |

| Heating zones | 22 zones |

| Inner cooling system | By blow cooling air , 7.5 kw with inverter control. |

| Material of calibrating sleeves | Stainless steel with chrome plated |

| Flow channel | Hardened and Mirror polishing |

| Pipe Bright function | With HYPET brighter |

| Heater | Mica stainless steel heaters |

6.Vacuum tank in 9,000 mm:

| Material | Stainless steel 304 |

| Working range | Ø250- Ø630 mm |

| Length | 12000mm |

| Center height | 1150 mm |

| Vacuum Tank type | One tank, in two chamber |

| No. of pipes | 1 pipe |

| Movable motor power | 0.75 kW |

| Moving range front & rear | 700 mm |

| Left and right adjustment | 100mm |

| Cover on the top | aluminium alloy |

| Vacuum pump in first part | 7.5kw *1 set |

| Vacuum pump in second part | 7.5kw *2 sets |

| Two parts of tank | Vacuum controlled by AC inverter. |

| Water pump in first part | 7.5kw *1 sets |

| Vacuum pump in second part | 7.5kw *4 sets |

| |

| Number of Nozzles | 530 pcs |

| What spray pipe numbers | 8 pieces |

Nozzle type

| Atomized intensive cooling |

Spraying mouth

| 1” x Ø4~Ø3 |

| Pipe supporter | Nylon supporter plate

|

| Back and forth | 800mm in 0.75kw |

Cross movement

| 120mm |

| Up and down | 100mm |

| Filter | 2 sets in G2” with by pass way |

| Clean the filter | By pass line for cleaning the filter |

| Vacuum cyclone | Yes, with it |

| Silence function | Silence device for each vacuum pump |

| Water temperature control | Auto valve control |

| Water level control | Floating ball close loop system |

| Pressure safety | Safety valve installed |

| Roller material | Nylon and others |

| direction | Round in any direction |

| Quantity | 2 sets |

| Adjust way | By manual |

7.Cooling tank in 9,000 mm:

| Specification | Description |

| Material | Stainless steel 304 |

| Pipe range | Ø250~Ø630mm |

| Length of vacuum box | 9,000mm |

| Pump power | 7.5 kW x 1 set |

| No.of nozzle | 320 pcs |

| No.of filter | 1 set |

| No. of bypass | 1 set |

| Water level control way | Float valve |

| Water temperature control | Automatic regulating valve |

8.Haul off unit, 6 claws:

| Specification | Description |

| Haul off type | 6 claw type haul off with servo control |

| Center height | 1150mm |

| For Pipe size | Ø250~Ø630mm |

| Driving method | Driven by rubber blocks |

| Driving speed | 0.17-1.7 m/min |

| Motor type | Servo motor |

| Motor power | 0.85 kW x 6 sets in servo motor control |

| Contacted caterpillar length | 2,200mm |

| Max. driving power | 100,000 N |

| Gear box | Hard surface gear grind type, |

| Width of caterpillar | 74mm |

| Metering system | Code installed |

| Adjusting mode | Pneumatic |

| Press pressure on the pipe | Adjusted by pneumatic valves |

| Down caterpillar position | Fixed |

| Air pressure | 0.4-0.6Mpa |

9.Dustless planetary blade cutter :

| Specification | Description |

| Cutting type | Dustless planetary blade cutting |

| Blade style | Sharp knife in two devices |

| Control system | PLC automatic control system |

| Cutting range | Ø250~Ø630mm |

| Cutter speed | 2.5 m/min |

| Max. cutting thickness | 60 mm |

| Cutter motor power | 3kw |

| Center height | 1500mm |

| Revolution motor power | 1.5 kW x 1 set |

| Cutter material | Tool alloy |

| Clamping way | Roller + rubber block by air |

| Cutter feeding | Double hydraulic |

| Hydraulic station | 0.75 kW x 2 sets |

| Synchronous mode | With output and haul off speed |

After -sales Service

| Items | quantity |

| Guarantee period | 1 year but the service is available lifelong, during guarantee

period the cost of the components will be covered by the seller

except the easy broken parts and damaged parts by the human reason |

| Training before shipping | Buyer’s technical person can be sent to china before shipping for

training and operating, for 7-10 days |

| Technical documents | Electric principle drawing, operation manual, and electric parts

manual etc |

| Seller engineers | Seller can send the engineers ot the buyer factory for

commissioning and training. But the cost caused by the seller

experts in the customer country will be covered by the buyer,

including shuttle trip tickets inland traffic medical fee, lodging

dinner and also 100 USD /day /one person as salary for the

enigneers . |

| Contacts way | Whatsapp, wechat, mobile, etc +86 13823232106 |

| Company email : | info@hypet.com.cn |

Cooperative Brands:

Exhibition: