Located in Shenzhen City which is the

most lively and youngest top city in China, it's next to HongKong

and Guangzhou City.

Shenzhen HYPET founded in 2002, and it

inherits from China national extrusion machinery entrerprise. Base

on Germany and Italian technology, HYPET invented and manufacture

unique gear box with own patent. For these reason to keep HYPET

tech and machine quality priority in extrusion machine field.

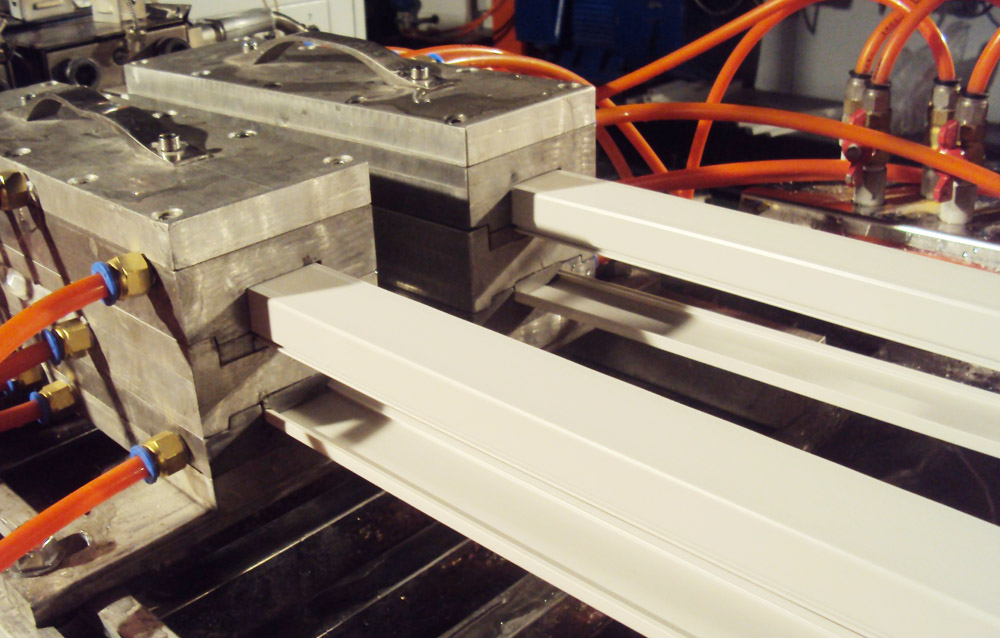

The first block type DIY plastic extruder

solves the machine agents' many problem. They can easily get

extruder parts from HYPET factory then assembles them in their own

workshop via the installation video.

The plastic extrusion line core part is the

extruder. If the extruder is good, then the line 70% is good. So

HYPET offer the service to match local downstream or old downstream

service.

Shenzhen HYPET machine is focus on top

quality but best enconomic price. Our main plastic extrusion

machine includes but not limited PVC / HDPE / PPR pipes

extrusion production line, PVC and WPC all type of profiles (PVC

window, ceiling, wallpanel, decking, gutter,

duct...) production line, PVC plastic marble sheet line, SPC

floor production line, WPC door plant, PVC foam board line,

Nonweave melt blown fabric line.....

HYPET also offer the special PVC

processing aid to decrease your final product cost and increase the

product quaity & better shining surface.

We have a full technical team can help you

design, manufacture, assemble, inspect and test the plastic machine

meet your request.